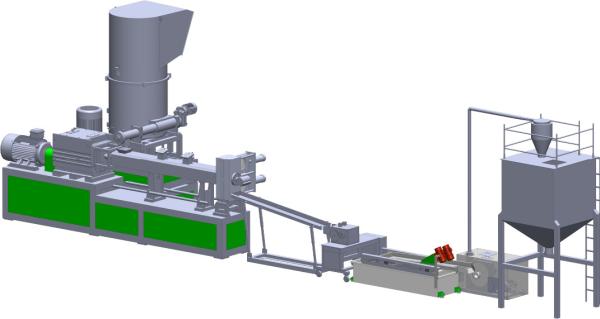

Customization Polyester PET sheet and Master batch Plastic

Pelletizing Recycling Machine

Project Analysis:

customer would like to recycle PET fiber, PET bottle flake and

sheet. to ensure its compounding, customer also would like to add

some master batach for final pellets color and transparent.

If PET fiber water content is more than 1%, we also need dry

plastic fiber. considering PET fiber strength, to equip plastic

shredder for crushing and feeding.

While PET bottle flake or crushed sheet get feed by screw loader.

Master batch get feed by side feeding screw, which is beside the

shredding compactor.

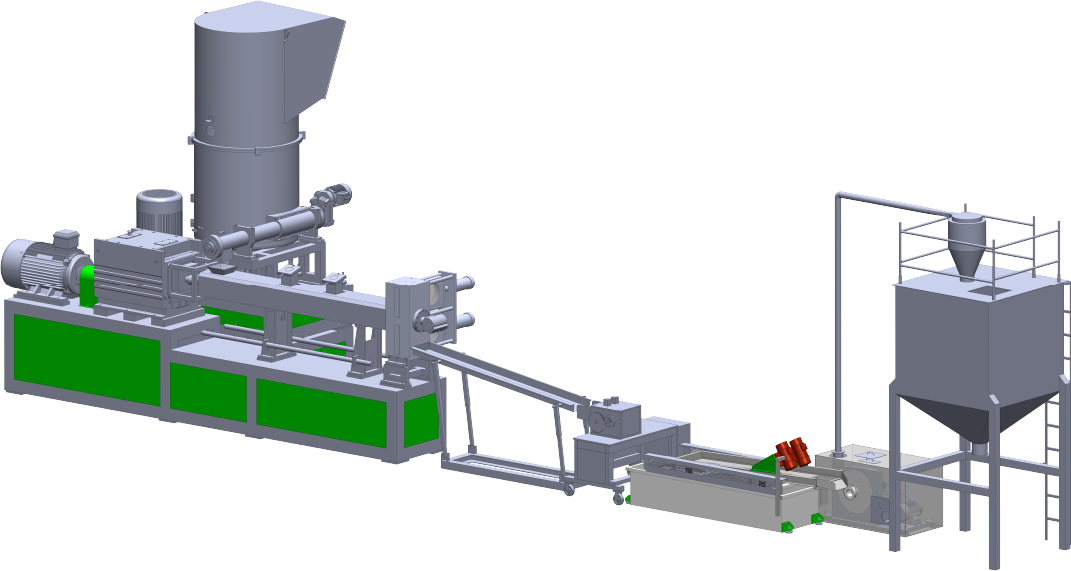

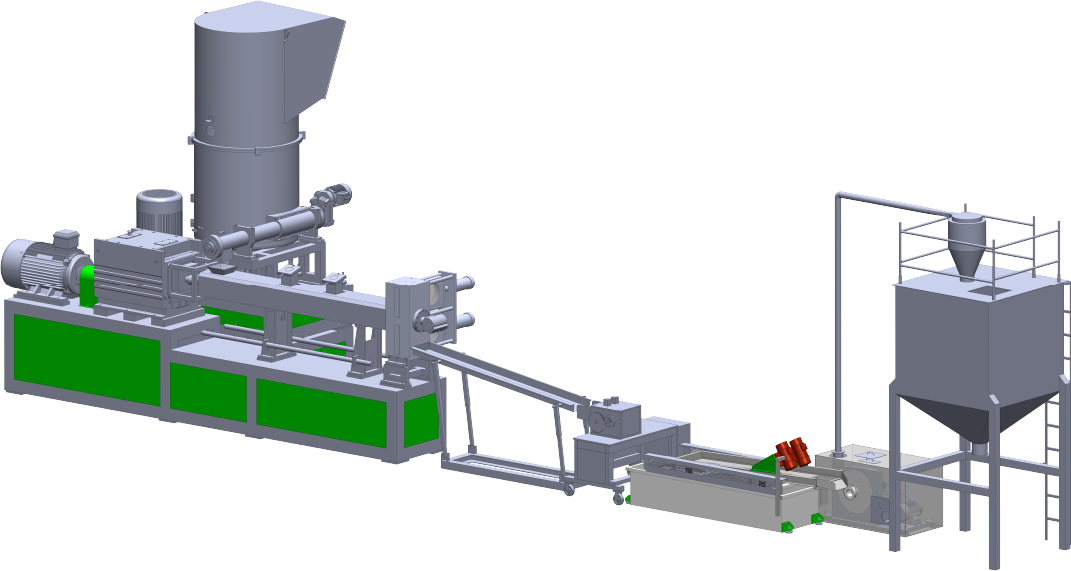

Working Flow:

Belt Conveyor- Plastic Shredder-Belt Conveyor with Metal Detector-

Shredding Compactor - Spiral feeder for PET sheet- side screw

feeder with vacuum feeder-ML100/38 Single Screw Extruder -Hydraulic

Screen Changer- Water Tank- -Water tank-Centrifugal Dewatering

System-Vibration System-Storage Silo-Vertical Mixer

Mian Techinical Parameter (high efficiency with power saving)

| Model | CT110 | CT120 | CT130 | CT150 | CT160 |

| Screw diameter(mm) | 110 | 120 | 130 | 150 | 160 |

| L/D | 28 to 32 |

| Output(kg/h) | 300 to 400 | 500 to 600 | 600 to 800 | 1000 to 1500 | 1500 to 2000 |

Working Process

Belt conveyor feed material into shredder

while shredding scrap go into shredding compactor for pre-cutting,

pre-homogenization, pre-plastification

Through friction force between compactor rotary cutters and fixed

cutters, material get shrinked

The shrinked material get melted in main extruder by heating and

cooling

Water ring cutting system cut the melt plastic into pellets

Why Choose Us

A.PR has professional manufacturer since 2006. we have our own

technical design department. Each extruder get designed according

to material feature.

B.Power saving with high output

C.Quality guaranty time is 12 months since the Bill of Lading date.

D.Delivery time: 40 work days to 60 days

E.Ship requested package

F.Machine installation is aboard available. It takes about 5 to 7

days with completing one time of installation. The assigned

engineer(s) manage the machine user training, machine operation and

commission

General Introduction

| Model name | ML |

| output | Plastic pellets/granules/resins/plastic raw material |

| Machine parts | Belt conveyor, cutter compactor, main extruder, pelletizing unit,

cooling system, silo, cabinet |

| Recycling material | PP/PE/LDPE/HDPE film, bag, fiber |

| Capacity range | 100kg/h to 1200kg/h |

| Feeding way | Conveyor, roll driving system |

| Screw diameter | 75mm to 200mm |

| Screw L/D | 26 to 33 |

| Screw raw material | 38CrMoAl or bimetallic |

| degassing | Natural degassing, vacuum degassing |

| Cutting type | Vertical pelletizing way, pull strip pelletizing |

| Cooling type | Water cool, air cool |

| voltage | Customized |

| Optional devices | Metal detector, water cooling system, feeding silo, vibration

system |

| Delivery time | 40 to 60 days |

| Warranty time | 13 months |

| Technical supports | Machine layout, installation layout, engineer oversea service |

| Certificate | CE/ SGS/ TUV/CO |

Machine Pictures

Feeding system 2

Side screw with master batch feeder

Recycling Machine Running Video