Automatic BOPET Film Recycling Pelletizing Extruder Machine

Mian Techinical Parameter (high efficiency with power saving)

| Model | ML75 | ML85 | ML100 | ML130 | ML160 | ML180 | ML200 |

| Screw diameter(mm) | 75 | 85 | 100 | 130 | 160 | 180 | 200 |

| L/D | 26 to 37 |

| Output(kg/h) | 100-150 | 200-350 | 400 to 550 | 600 to 800 | 800 to 1000 | 1000 to 1200 | 1200 to 1500 |

Working Process

Belt conveyor feed material into shredding compactor , both parts

get designed with inter-lock

Material get pre-heated, pre-homogenized and pre-plastification

during shredding compactor

Through friction force between compactor rotary cutters and fixed

cutters, material get shrinked

The shrinked material get melted in main extruder by heating and

cooling

Water ring cutting system cut the melt plastic into pellets

Key Features

Energy Efficiency and Automation

Low energy consumption.

Stable output.

Low noise operation.

High automation.

Quality Output

Produces smooth plastic pellets.

Experience and Certification

Over 20 years in exports.

Various industry certifications.

Warranty and Support

One-year warranty.

Extensive after-sales service.

Recycling Capability

This pelletizer recycles:

Waste and rejected materials.

Leftover and inferior products.

Film plastics for reuse.

We offer standard models and custom designs. With over 20 years in

the industry, we lead in product quality and performance. Our

after-sales support ensures maintenance for all customers.

Fully Automatic Operation

Key features include:

Optional extruder vent.

Different pelletizing methods.

Large filtration area with no downtime.

Compact design with excellent performance.

We also provide a cleaning machine for dirty films.

Suitable Raw Materials

Main Advantages:

Versatile Recycling: Works with PE, PP, BOPP, LDPE, LLDPE, PA, PET,

and wet plastics.

Downtime Reduction: Hydraulic lifting for easy filter replacement.

Stable Operation: High-torque gearbox for smooth, quiet

performance.

Improved Mixing: Special design reduces black spots.

Enhanced Production: Forced feeding and quick screen changer for

higher capacity.

Reliable Exhaust System: Efficient discharge of water vapor and

impurities.

Conclusion:

Our plastic film pelletizer provides an efficient solution for

recycling plastics. We focus on quality and customer satisfaction.

Each machine meets high standards, ensuring confidence in your

purchase.

General Introduction

| Model name | ML |

| output | Plastic pellets/granules/resins/plastic raw material |

| Machine parts | Belt conveyor, cutter compactor, main extruder, pelletizing unit,

cooling system, silo, cabinet |

| Recycling material | PP/PE/LDPE/HDPE film, bag, fiber |

| Capacity range | 100kg/h to 1200kg/h |

| Feeding way | Conveyor, roll driving system |

| Screw diameter | 75mm to 200mm |

| Screw L/D | 26 to 33 |

| Screw raw material | 38CrMoAl or bimetallic |

| degassing | Natural degassing, vacuum degassing |

| Cutting type | Vertical pelletizing way, pull strip pelletizing |

| Cooling type | Water cool, air cool |

| voltage | Customized |

| Optional devices | Metal detector, water cooling system, feeding silo, vibration

system |

| Delivery time | 40 to 60 days |

| Warranty time | 13 months |

| Technical supports | Machine layout, installation layout, engineer oversea service |

| Certificate | CE/ SGS/ TUV/CO |

Machine Pictures

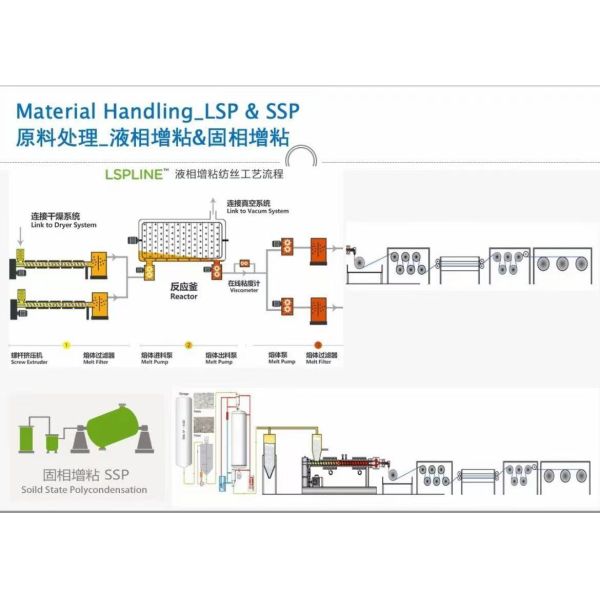

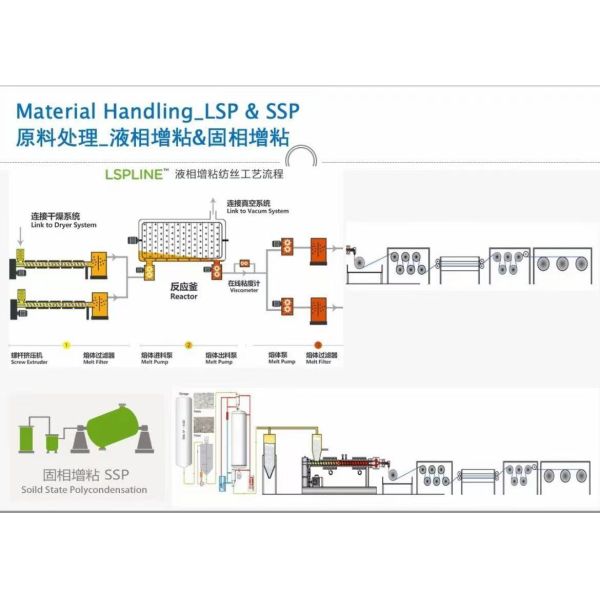

Solid State Polymerization for IV increasing

The solid state polymerization of pellets is carried out by this

special designed reactor device.

The chips enter into the drum and is vacuumed by heating.

Before SSP process, by certain heating rate, the crystallization

and drying process are carried out first, then the temperature is

raised to make it reach the temperature of solid state

polymerization.

Under the high vacuum condition, the monomer produced by the

reaction is removed to make it polymerize continuously until it

reaches the high viscosity product.

Solid State Polymerization Combination:

Vacuum system

I

Feeding system - - - SSP reactor system - - - Packing system

I

Heating/ Cooling system

SSP designed system

Feature and advantages:

1. power saving with compact structure

2. reliable and reasonbale design

3. easy operation

4. long servie life

5. reactor get non-linking test by professional equipment with

excellent seal ring

6. whole system keep on pressure testing before export workshop

7. skilled welders go on sophiscated operation and prosuction