PET Bottle Recycling Machines and Recycling Machines

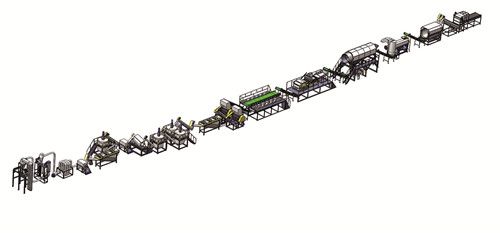

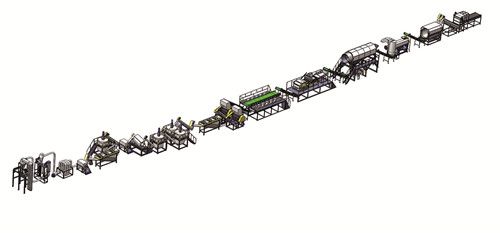

PET bottle washing line /PET bottle recycling plant/PET recycling

process

PR Recycling Machine (Label Separating, Crushing, Washing, Drying and Granulating)

PET Bottle Recycle Washing Machines are special designed for PET bottle with sand, stone, powder, oil and other sticky waste.

Capacity range: 500kg/h to 6500kg/h

PR Recycling Machine Information

Plastic bottle label separating, cutting, washing, recycling machine with high output and excellent

clean ability

Whole plastic recycling line is used to crush, wash, dewater and

dry the PP/PE flake or rigid material

Simple structure, easy operation, large capacity, energy-saving,

safety

Automatic controlling, compacted structure, excellent production

ability, perfect clean ability

1-Iron board chain with Bale breaker

2-Incline belt conveyor

3-Roll trommel

4-Manual plate with magnetic separator

5-Belt conveyor (2 sets)

6-Plastic granulator(2 sets)

7-Spiral feeder (2 sets)

8-Low speed friction washer

9-floating tank with bottom discharge screw

10-spiral feeder

11-hot washer with water filtering system

12-high speed friction washer

13-spiral feeder

14-floating tank B

15-spiral feeder

16-spray washer

17-centrifugal dewatering system

18-label remover

19-round vibration system

20-up loader

21-optical sorter (color)

22-color collector

23-silo

24-control cabinet

Technical parameter of PET bottle washing line

| Capacity(kg/hr) | Power installed (kW) | Warehouse are( m2) | Manpower | Water supply (m3/h) |

| 500 | 116 | 1500 | 4 | 5 |

| 1000 | 200 | 1800 | 5 | 6 |

| 2000 | 406 | 2000 | 5 | 8 |

| 3000 | 500 | 2500 | 6 | 10 |

Output PET flake quality reference

| Moisture content | <0.9% | Label | <19ppm |

| PVC | <49ppm | Variegated tablets | <28ppm |

| glue | <10.5ppm | PH | (neutral) |

| PP/PE | <19ppm | Total impurity | <100ppm |

| Metal | <18ppm | Flake size | 12mm,14mm(customization) |

Production Consumption

| Items | Average Consumption Per Ton Flakes |

| Electricity(kwh) | 170 |

| Steam(kg) | 510 |

| Washing Detergent(kg/ton) | 5 |

| Water | 2 |

Machine Detail Pictures:

Belt conveyor or Iron board chain

Bale Opener

below 1000kg/hr, to use vertical bale opener

surpass 1000kg/hr, to use 4 shafts bale broker

Bottle Label Scrapper

Plastic Granulator or plastic crusher

It is specially designed for PET bottle crushing. The blades are

made of imported high qulity material, featured by long life span.

Easy to change baldes with lower powder prodcuing during crushing

process

Floating Tank

Labels and caps scraps with a specific gravity smaller than water,

they are floating on the water, while bottle flakes with a specific

gravity than water will sink in the tank

PET bottle flakes, labels and bottle caps can be separated in the

floating washing process

Hot Washer

To hot water with 80 degree for sticky and smelly waste removing

To add soda chemical for intensive washer with steam

Material feeding acoring to tiny waste gravity

water filtering system can be choosed as optional parts

Label Separator

It is intentionary designed to remove PVC label scraps and dust in

PET flake

99.9% seperating efficiency