Power Saving Plastic Film Squeezing Dryer

Plastic Film Squeezing Dryer

Plastic squeezer is a kind of equipment used in plastic processing

industry, which is mainly used to squeeze and dry plastic raw

materials (such as granules or sheets) through heating and

mechanical action.

It usually plays a key role in plastic recycling, reprocessing and

production.

Washed film typically retains up to 40% moisture, which can pose

challenges for post-consumer recyclers.

Traditional horizontal dryers often struggle to effectively remove

moisture from lightweight film scraps and flakes, leaving about

15-20% water content after drying.

This excessive moisture can lead to inconsistent feeding and

reduced output in the pelletizing extruder.

The squeezer drying machine provides a fast and efficient solution,

reducing moisture levels from 20-40% down to just 3-5%, thereby

alleviating pressure on the recycling extruder.

This process generates less heat, resulting in reduced material

degradation and higher quality, more reusable recycled pellets.

Additionally, it transforms film scraps into solid flakes with

higher bulk density, reducing volume and enabling faster, easier,

and more stable feeding into the recycling extruder.

Main function:

Extrusion: Heat plastic granules to a molten state and extrude

plastic products of the densify through a die.

Dehydration: The squeezer can remove moisture from the plastic and

improve the efficiency of pelletizing processing.

Mixing: Different types of plastics or additives can be mixed to

improve their performance.

Main components:

Screw: 38CrMoAl Screw and Barrel, which responsible for pushing and

mixing plastic raw materials.

Heating ring: Used to heat the screw and barrel to melt the plastic

Mold: Used to form products of specific shapes.

Control system: Monitor and adjust parameters such as temperature

and pressure by PLC control system or control cabinet Application

field

Machine Feature:

Integrated screw and barrel avoid broking easily than welded screw

Strong gear box offer enough stenfth for whole system

Smart control with PLC touch screen and frequency inverter

Anti-blocking system for feeding part, which can avoid material

block(anti-brige)

Output water content after plastic squeezer is 3% to 5%

Technical Parameter of plastic squeezer

| Model | NG250 | NG300 | NG320 | NG350 | NG380 |

| PE Capacity(kg/hr) | 300 | 500 | 800 | 1000 | 1400 |

PP Capacity(kg/hr) | 200 | 400 | 500 | 600 | 800 |

Application:

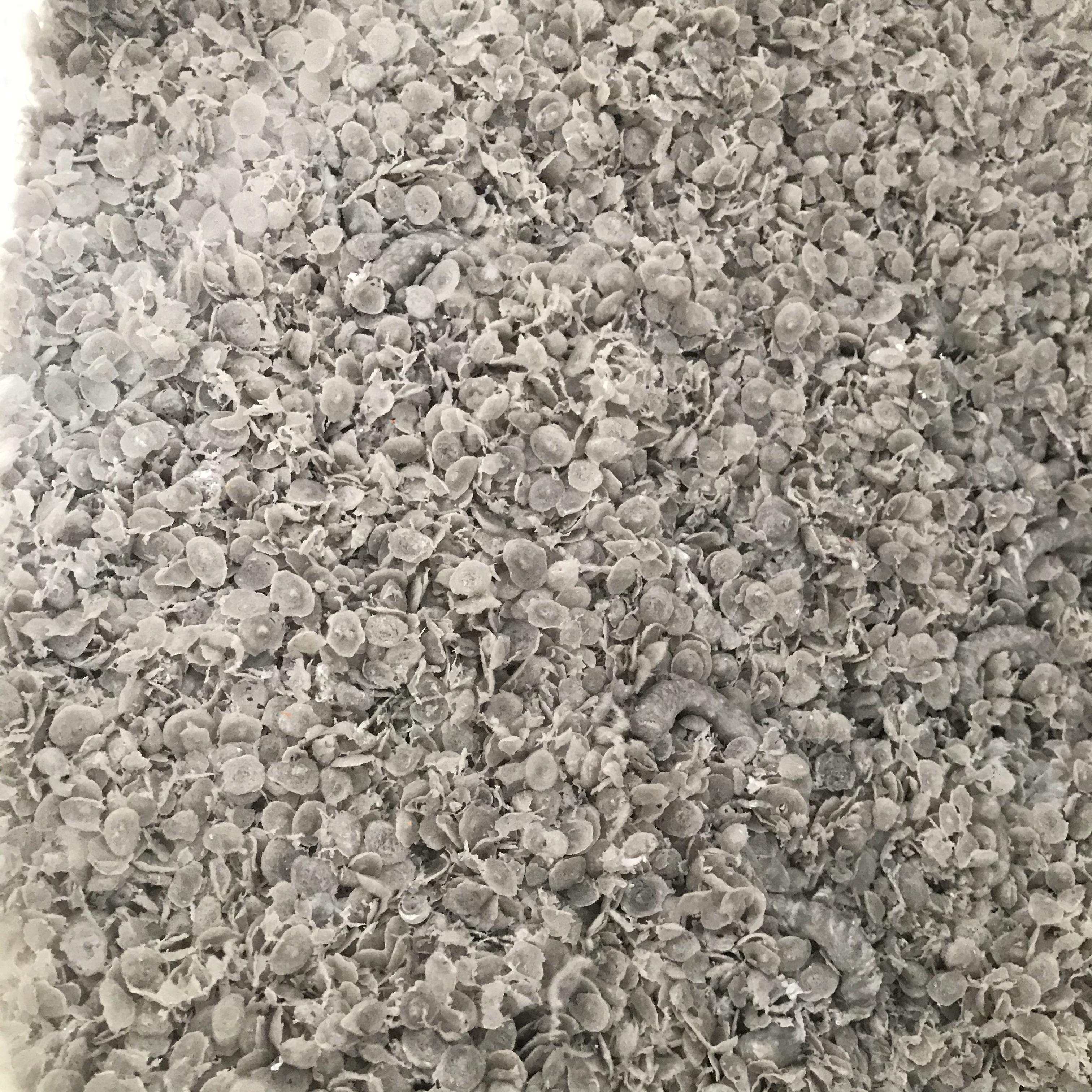

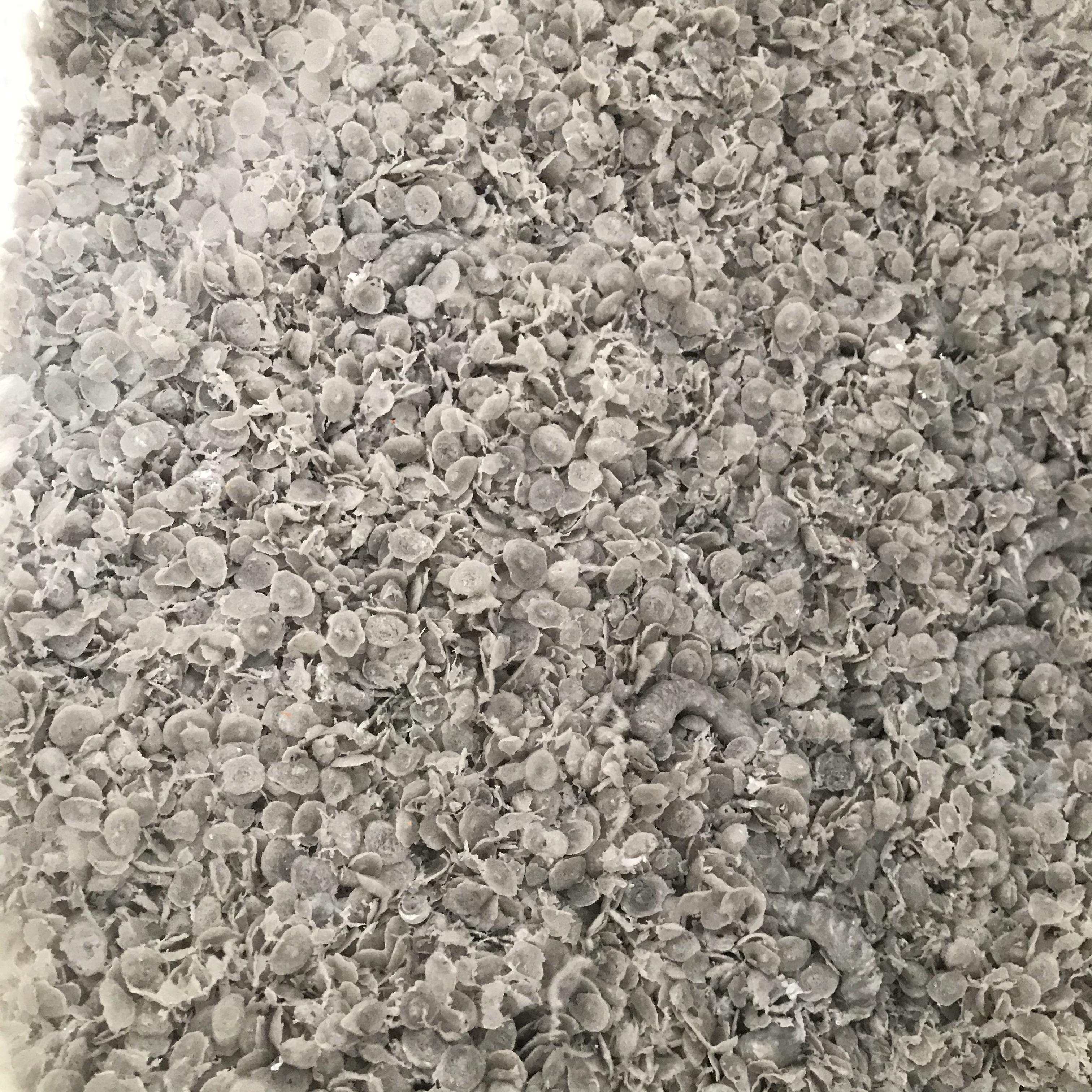

PE Film Plastic Squeezer Plastic recycling: Recycle waste plastics and reduce environmental

pollution.

Plastic manufacturing: Produce various plastic products, such as

pipes, films, bottles, etc.

Composite materials: Mix with other materials to prepare new

composite materials.

Main Machine Pictures